Why is traceability of recycled plastic important?

Traceability of recycled materials helps prove the origin of pre- and post-consumer plastic waste used, leading to more reliable recycled content claims.

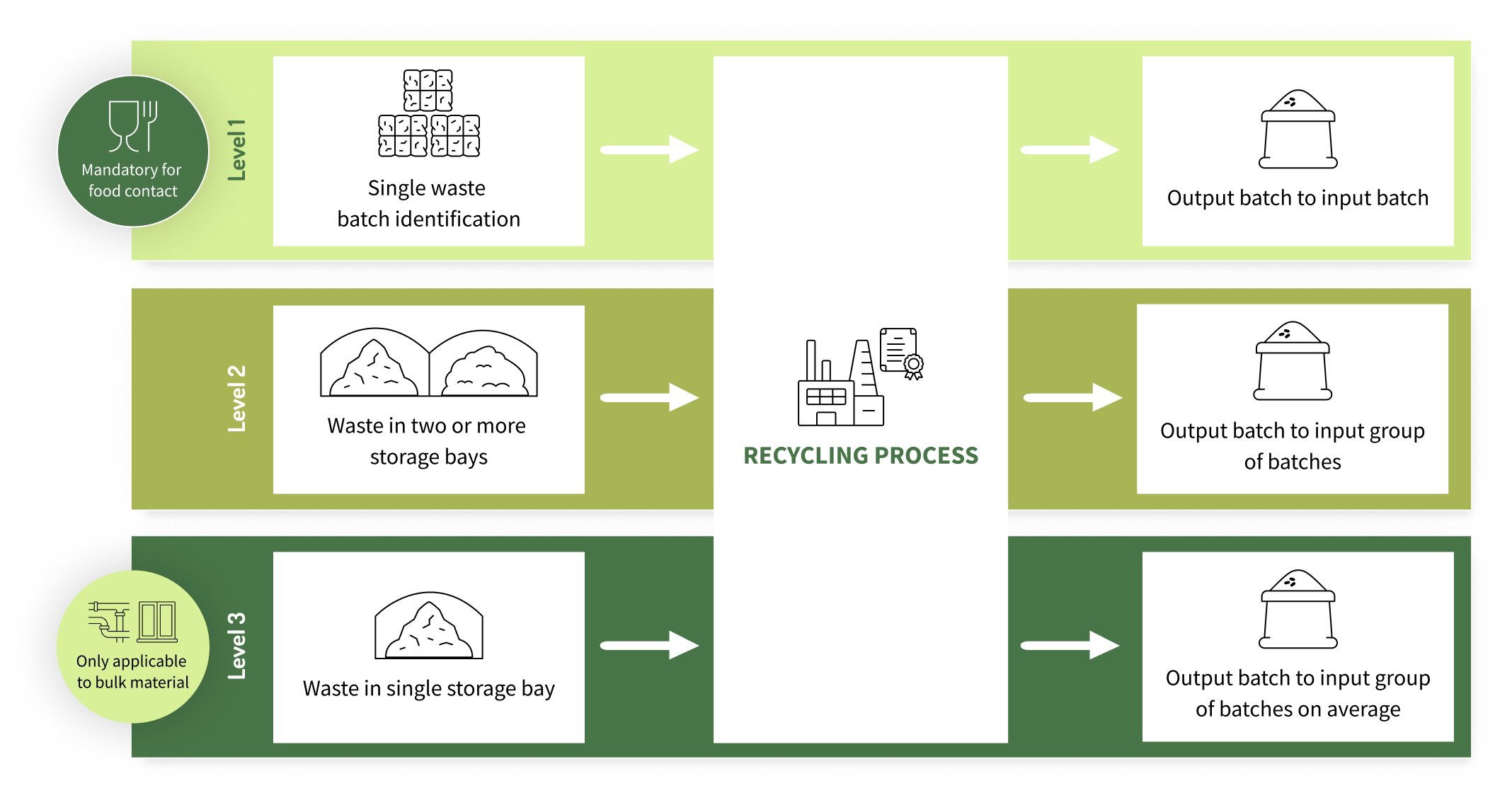

There are three main traceability levels:

TRACEABILITY LEVELS

HOW TO CALCULATE

RECYCLED PLASTIC?

A number of methods exist for calculating recycled plastic content in products, covering both mechanical and chemical recycling processes. These methods differ based on how materials are traced throughout the plastics value chain and the level of traceability they provide.

The chosen calculation method directly influences the credibility of recycled content claims. For example, a method with high traceability allows for more specific and verifiable declarations.

European standard EN 15343:2007 describes how to calculate recycled content in a product.

How does this calculation

work IN PRACTICE?

The amount of recycled content that a brand owner can use in their products may vary depending on different factors, such as the availability of material or suppliers of recycled plastics – this means that very often the amount of recycled content in a destined product can vary from one period to another.

Based on the methodology used, the amount of recycled plastic incorporated in each product will be reported and claimed differently.

What is the method Followed by Recyclass?

RecyClass follows a controlled blending approach. This model focuses on the physical traceability of materials throughout the entire recycling process, which means that at any given time the percentage of recycled content is known. When following this calculation method, it is possible to make claims on products such as: “This bottle contains 60% recycled plastic.”

Because this model certified a known percentage of recycled plastic, it ensures reliable, understandable and trustworthy communication towards stakeholders, customers and consumers.